| Brand Name: | FDS |

|---|---|

| Micro Machining or Not: | Micro Machining |

| Material Capabilities: | Aluminum,Brass,Bronze,Copper,Hardened Metals,Precious Metals,Stainless Steel,Steel Alloys, |

| Type: | Broaching,Drilling,Etching / Chemical Machining,Laser Machining,Milling,Other Machining Services,Rapid Prototyping,Turning |

| CNC Machining or Not: | CNC Machining |

Quick Details

Specifications

about Us:

Dongguan Kohong Hardware Technology Co., Ltd is one of the world's leading designers and manufacturers of high-quality custom metal stamping parts, and CNC-machined, injection, welded, and laser-cut parts. We manufacture high-volume metal stamped parts, CNC-machined parts, metal components, metal deep-drawn parts and metal insert molds for a wide range of industrial sectors, which include electrical, electronic, medical, automotive, telecommunication, and solar energy.

Turning out up to 200 Million Pressed Metal Parts and Plastics Monthly

Our products are exported to customers in the US, Europe, Latin, South America, Asia, South Africa, and Australasia. We have the capacity to produce up to 200 million pressed custom metal parts and plastics per month with our metal pressing machines.

Assisting Customers with Initial Design and Concept

Our expertise extends to assisting customers with the initial design and concept, including the choice of raw materials. We have developed close working relationships with industry-leading producers of non-ferrous alloys and can identify "cost down" solutions before a die is built.

We accept OEM&ODM CNC machined processing.Raw material about Aluminum,Brass,steel,and stainess steel,our CNC machined parts can be up to 0.01mm tolerance.2m*500mm CNC machined parts can be made in our factory. We provide one-stop services

and own independent right of import and export.

Be Our Partner Today

If you are interested in our products and services, contact us today.

Key Specifications/ Special Features:

High precision deep drawing metal stamping parts:

1. Materials: aluminum alloy, iron, steel, stainless steel, brass, aluminum and other materials

2. Specification: according to drawings and samples

3. Thickness: customized

4. Surface treatment: zinc plated, power coated, chrome plated, hot-dip galvanized

5. Packing: carton box, pallet, strong box or according to client's requests

6. We are willing to provide with sample for quality and function testing

Types of plant and machinery in factory:

-Complete stamping die mold room equipment

-High-speed punch presses

-Pneumatic punching machines

-Variety of tonnage equipment

-Distinguished

-Specialized

-Refined

-Sophisticated

Our services:

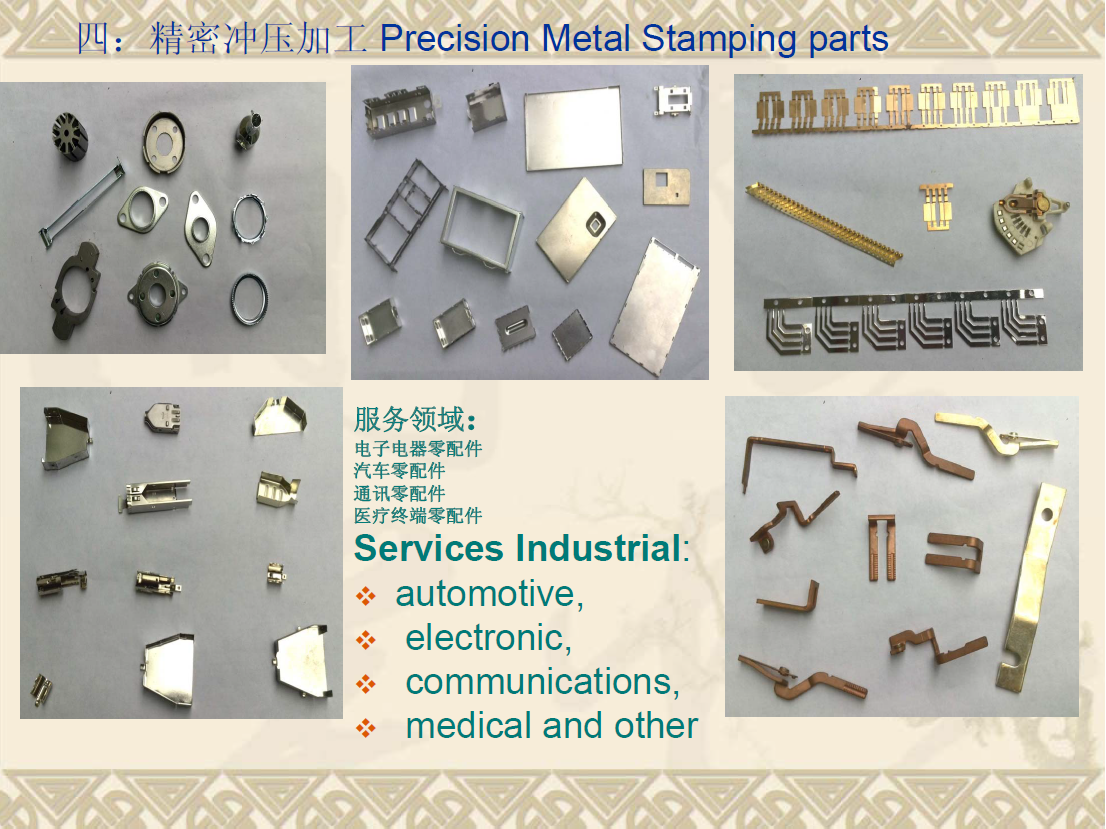

Automotive

Electronic

Communications

Medical and other

Certifications:

- IATF 16949 certified

- ISO 9001:2008 certified

- ICP test report

Special capability:

Prototyping

Quick turnaround specialist

Flexible manufacturing response

Contract stamping-short, medium and long run

High-speed capabilities

Progressive and compound tooling for materials starting at 0.002" thick

Value added processes:

Heat treating

Metal finish

Assembly

Concurrent engineering

Place of origin:Guangdong, China (Mainland)Payment termsT/T

Materials:stainless steel, aluminum, steel, brassSurface finish:according to customer's requirements

Size:according to your drawing or our existing partsUses:industrial, precision metal stamping product

Certifications:ISO 9001:2008, SGS or RoHS Directive-compliantSample time:free sample existing in stock, 3-15 days for open mold

Model number:as your drawing part numberQuality guarantee:100% responsible for quality problems

Process:metal stamping, punching, bending, forming,Market:all over the world

Dongguan Kohong Hardware Technology Co., Ltd is one of the world's leading designers and manufacturers of high-quality custom metal stamping parts, and CNC-machined, injection, welded, and laser-cut parts. We manufacture high-volume metal stamped parts, CNC-machined parts, metal components, metal deep-drawn parts and metal insert molds for a wide range of industrial sectors, which include electrical, electronic, medical, automotive, telecommunication, and solar energy.

Turning out up to 200 Million Pressed Metal Parts and Plastics Monthly

Our products are exported to customers in the US, Europe, Latin, South America, Asia, South Africa, and Australasia. We have the capacity to produce up to 200 million pressed custom metal parts and plastics per month with our metal pressing machines.

Assisting Customers with Initial Design and Concept

Our expertise extends to assisting customers with the initial design and concept, including the choice of raw materials. We have developed close working relationships with industry-leading producers of non-ferrous alloys and can identify "cost down" solutions before a die is built.

We accept OEM&ODM CNC machined processing.Raw material about Aluminum,Brass,steel,and stainess steel,our CNC machined parts can be up to 0.01mm tolerance.2m*500mm CNC machined parts can be made in our factory. We provide one-stop services

and own independent right of import and export.

Be Our Partner Today

If you are interested in our products and services, contact us today.

Key Specifications/ Special Features:

High precision deep drawing metal stamping parts:

1. Materials: aluminum alloy, iron, steel, stainless steel, brass, aluminum and other materials

2. Specification: according to drawings and samples

3. Thickness: customized

4. Surface treatment: zinc plated, power coated, chrome plated, hot-dip galvanized

5. Packing: carton box, pallet, strong box or according to client's requests

6. We are willing to provide with sample for quality and function testing

Types of plant and machinery in factory:

-Complete stamping die mold room equipment

-High-speed punch presses

-Pneumatic punching machines

-Variety of tonnage equipment

-Distinguished

-Specialized

-Refined

-Sophisticated

Our services:

Automotive

Electronic

Communications

Medical and other

Certifications:

- IATF 16949 certified

- ISO 9001:2008 certified

- ICP test report

Special capability:

Prototyping

Quick turnaround specialist

Flexible manufacturing response

Contract stamping-short, medium and long run

High-speed capabilities

Progressive and compound tooling for materials starting at 0.002" thick

Value added processes:

Heat treating

Metal finish

Assembly

Concurrent engineering

Place of origin:Guangdong, China (Mainland)Payment termsT/T

Materials:stainless steel, aluminum, steel, brassSurface finish:according to customer's requirements

Size:according to your drawing or our existing partsUses:industrial, precision metal stamping product

Certifications:ISO 9001:2008, SGS or RoHS Directive-compliantSample time:free sample existing in stock, 3-15 days for open mold

Model number:as your drawing part numberQuality guarantee:100% responsible for quality problems

Process:metal stamping, punching, bending, forming,Market:all over the world